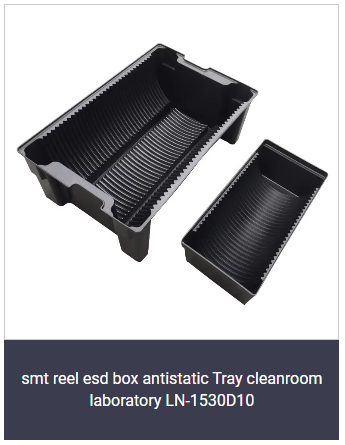

Injection-molded anti-static reel boxes are mainly used in fields such as electronic manufacturing and logistics transportation. They protect precision components from static damage through anti-static functions and provide efficient storage and handling solutions at the same time.

Core functions

1. Anti-static protection

With special materials and structural design, it can quickly conduct away static electricity and prevent damage to electronic components such as chips and circuit boards caused by electrostatic discharge (ESD). The surface resistance is stable within the range of 10^6 to 10^9Ω, in compliance with the standards of the International Electrotechnical Commission (IEC).

2. Durability and convenience

The injection molding process ensures that the pallet has high strength and good toughness, capable of withstanding frequent handling and stacking, and is not prone to deformation over long-term use. Grid or flat plate designs enhance air circulation efficiency and are suitable for clean workshops or logistics turnover scenarios.

3. Classification storage optimization

Customize compartments based on component sizes to achieve precise storage and improve retrieval efficiency. For instance, after being used by semiconductor enterprises, the component failure rate caused by static electricity was reduced to 0.002%.

4. Typical application scenarios

Electronic manufacturing: Component temporary storage and transportation in the production of integrated circuits and liquid crystal panels.

Logistics transportation: Anti-static protection in long-distance transportation of precision equipment.

Warehouse management: Classification storage of electronic components and maintenance of anti-static environment

| Packaging solutions for scattered components-Small Reel Tape Box/Reel Tray | |

| Diameter: | 177mm |

| Material: | PP |

| Cover Weight: | 27g |

| Box Weight: | 51g |

| Color: | Black |

| Surface resistance: | 10e6-10e9Ω |

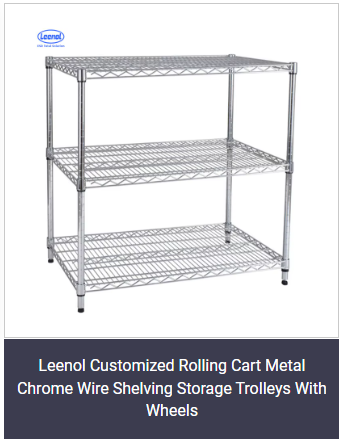

Related Products:

Our professional sales team are waiting for your consultation.