Stencil Inspection Machine

Basic Specification Parameters:

| Project | Specification | ||||||

| Voltage | 220V 50/60HZ 100W | ||||||

| Camera unit | 1000w industrial camera, 21X - 135X | ||||||

| Backlight | Large-area flat light | ||||||

| XY drive | X lead screw manual drive, Y belt drive | ||||||

| Monitor | 21.5inches 1080P | ||||||

| Stencil size | <736mm | ||||||

| Object steel mesh | 370-736mm | ||||||

| Machine size | L= 1000mm w=9O0mm H=1350mm |

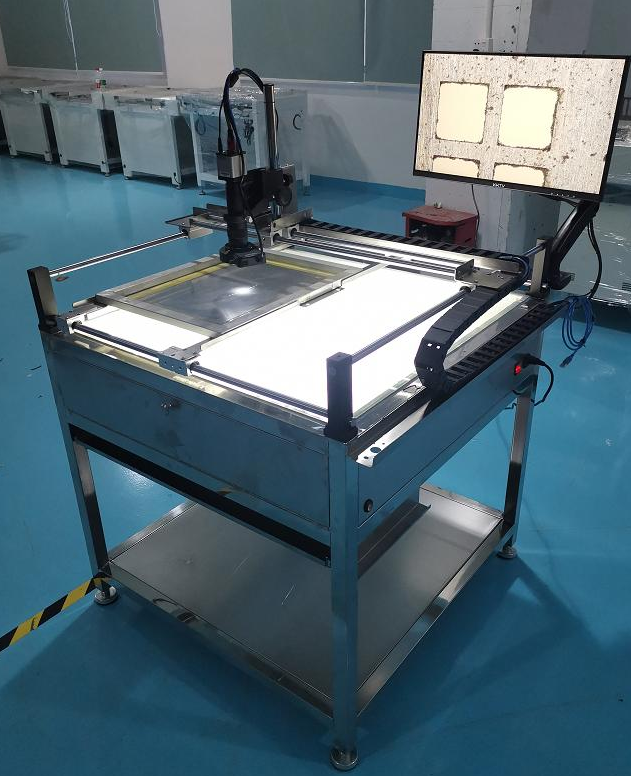

SVII-900 is an economical Stencil Inspection Machine . With the increasing precision in electronic product manufacturing and the widespread use of some ultra-small components,The printing technology is becoming increasingly sophisticated, and the cleaning quality of the steel mesh plays a very important role in the printing process. Currently, it is impossible to inspect the cleaning effect of the openings of small component steel meshes by relying solely on manual observation. However, the SVII-900 manual inspection machine is equipped with a high definition industrial camera. By combining with a plane light source and transmitting the captured opening images to the display for analysis, it reduces the detection difficulty, improves the detection accuracy and efficiency.

Equipment parameters:

1: Applicable steel mesh size: Maximum 736mm X 736mm X 40mm

2: Inspection method: Camera photography

3: Camera: 2 million pixels

4: Display: ASUS 17-inch

5: Backlight: LED backlight

7: Front lighting: LED circular lamp

8: X-axis: Linear guide rail

9: Y-axis: Linear guide rail

10: Z-axis: Linear guide rail + gear fine adjustment

11: Equipment size: 865mm X 860mm X 1530mm

Stencil Inspection Machine product feature:

1.Wide detection range:

Maximum detection area: 736x736mm

2. Strong versatility of the steel mesh:

Steel mesh size: 370MM - 736MM

3. Simple operation:

Manual real-time detection, simple and convenient

Basic Specification Parameters:

| Project | Specification | ||||||

| Voltage | 220V 50/60HZ 100W | ||||||

| Camera unit | 1000w industrial camera, 21X - 135X | ||||||

| Backlight | Large-area flat light | ||||||

| XY drive | X lead screw manual drive, Y belt drive | ||||||

| Monitor | 21.5inches 1080P | ||||||

| Stencil size | <736mm | ||||||

| Object steel mesh | 370-736mm | ||||||

| Machine size | L= 1000mm w=9O0mm H=1350mm | ||||||

| Machine weight | 75KG |

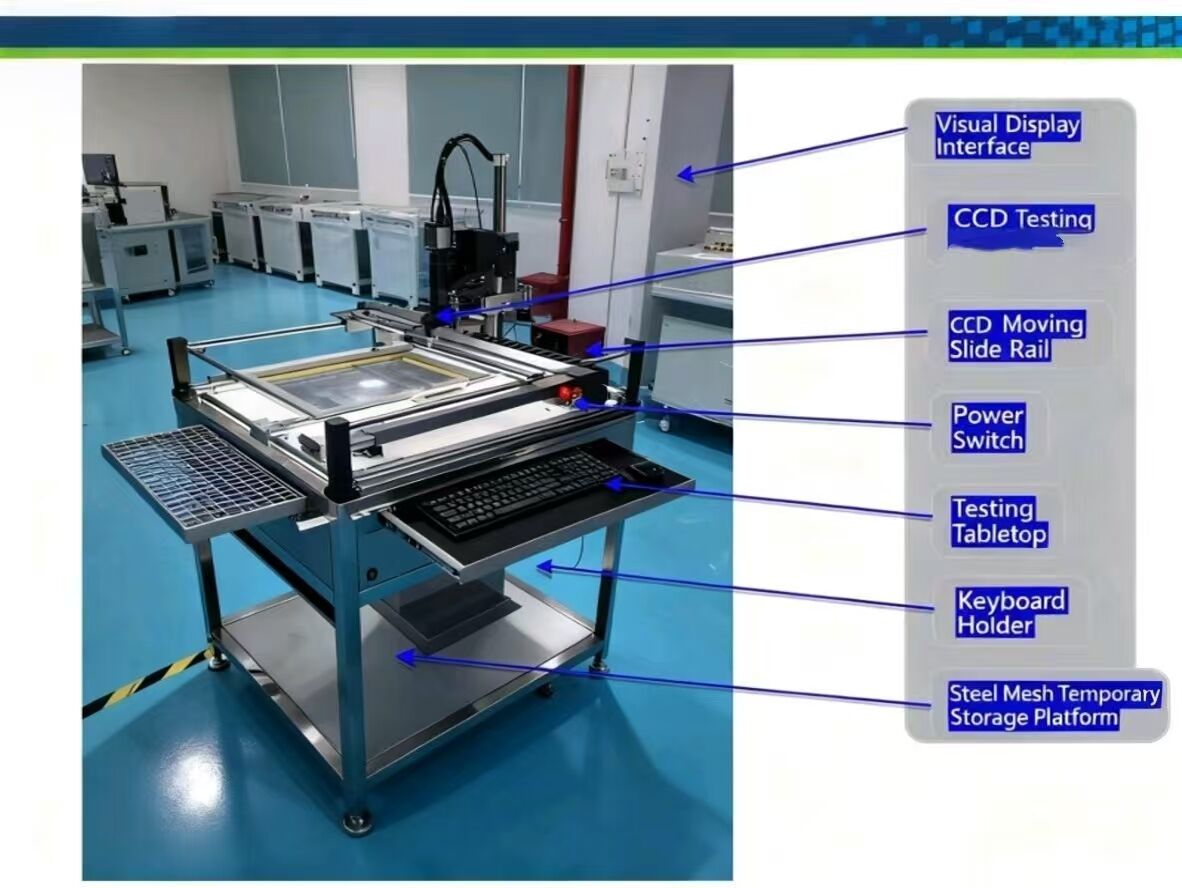

Machine composition

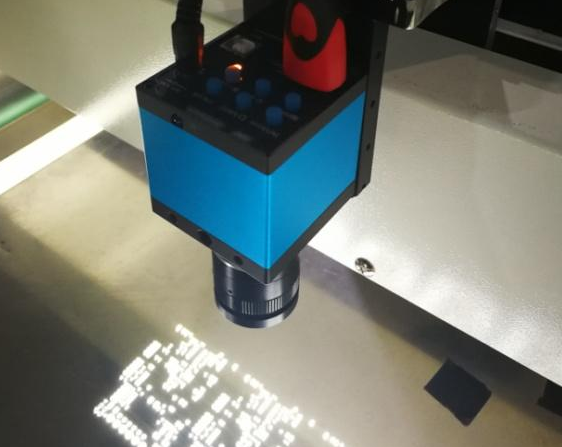

Visual Unit:

1. The 1000W industrial camera is an important component of the equipment, mainly responsible for hole position detection.

2. Backlight is very important and directly affects the clarity during the test. Please adjust the brightness of the light source according to the actual situation. The light source should be white.

appearance and structure:

Operation steps:

1. Connect the power supply and press the [Power] button.

2. Place the steel mesh to be tested horizontally on the [test table].

3. Turn on the [light source adjustment switch] and the backlight will work (white light).

4. Manually push the [slide rail handle] to control the X and Y directions, so that the [CCD testing mechanism] moves to the test position.

5. Observe the [visual display interface] for manual judgment.

Notes:

During operation, do not directly push the camera to avoid damaging the transmission mechanism and the camera itself. After the inspection is completed, please turn off the backlight to prevent reducing the lifespan of the light source.

Our professional sales team are waiting for your consultation.