Why are more and more enterprises choosing specialized Anti-static Storage Boxes?

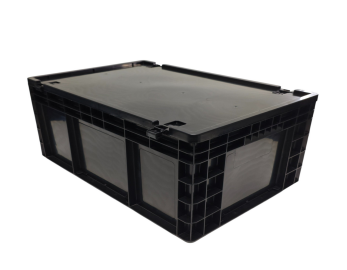

Traditional packaging materials like cardboard and wooden boxes often face challenges such as short lifespans, inconsistent specifications, and difficult management. However, specialized ESD Boxes/ESD Bins, with standardized designs, durable materials, and scientific structures, completely address these pain points.

- Durable and economical: A high-quality plastic ESD Bins can be recycled for 3-5 years, far exceeding the lifespan of disposable packaging. In the long run, this can help companies reduce packaging procurement costs by over 70%.

- Efficient space utilization:ESD Boxes Standardized dimensions increase warehouse space utilization by up to 40%. Neat stacking and convenient access reduce clutter in warehouses.

- Product protection: Esd Antistatic Conductive Box Dust-proof, moisture-resistant, and impact-resistant, they provide comprehensive protection for your products, significantly reducing damage during transportation.

How to choose the right ESD Turnover Box for your business?

ESD Boxes Select by Material:

Plastic ESD Boxes: Lightweight and durable, suitable for most applications

ESD Bins Metal crates: Strong load-bearing capacity, suitable for heavy parts

Antistatic Box Foldable design: Space-saving, suitable for empty return shipping

ESD Bins Select by Function:

Crates with ESD Bins: Dust-proof and moisture-resistant, suitable for precision parts

ESD Turnover Box Mesh : Ventilated and breathable, suitable for agricultural products

Anti-static Box: Specialized for electronics

Antistatic Conductive Box Select by Size:

It is recommended to first measure the shelf dimensions and the space available in your transport vehicle, then select the most suitable crate size to achieve a customized fit.

A Case Study of Customizing Our Company's Anti-Static Turnover Boxes: Improving Production Safety and Efficiency in an Electronics Manufacturing Enterprise

I. Project Background

An electronics manufacturing company primarily produces Precision Circuit Boards/PCB and semiconductor components. Because these products are extremely sensitive to static electricity, they have repeatedly experienced component failures due to static damage during storage and transportation. This not only caused financial losses but also impacted customer delivery cycles.

II. Problem Analysis

Traditional plastic turnover boxes lack Anti-Static properties and are prone to Static accumulation during handling and stacking.

The frequent flow of materials between production lines, combined with friction and humidity fluctuations, exacerbates static accumulation.

The lack of unified material management standards leads to component and PCB mixing and difficulty in traceability.

III. Solution

The company implemented an Anti-Static Box/ESD Bins system, customized by the supplier with the following features:

Conductive PP Box material is used, maintaining a surface resistivity between 10⁴ and 10⁶Ω;

Each Conductive PP Box model is equipped with Anti-Static Mats, label slots, and a stackable design;

Combined with dedicated SMT RACK and an Anti-Static Flooring system, this system provides ESD protection throughout the production line.

IV. Implementation Results

Improved Product Yield: The ESD damage rate was reduced from 0.8% to 0.05%.

Improved Logistics Efficiency: Standardized ESD Box/ESD Bins reduced warehousing and distribution time by approximately 20%.

Standardized Management: Material traceability is achieved through standardized numbering and color coding.

Improved Corporate Image: Obtained customer ESD protection certification, strengthening brand trust.

Professional crates bring more than just storage.

After implementing a standardized crate system, one home appliance manufacturer not only saw a complete transformation in its warehouse, but more importantly:

Production line delivery efficiency increased by 35%

Item loss rate decreased by 90%

Loading and unloading labor costs decreased by 50%

Overall logistics efficiency increased by 30%

These seemingly small changes have become crucial components of a company's competitiveness.

In the era of smart logistics, ESD Bins are also evolving.

Modern ESD Box are no longer simply containers; ESD Bins are a vital component of intelligent logistics systems. By adding RFID tags, ESD Turnover Boxes become mobile data collectors, tracking logistics activity in real time and providing businesses with accurate inventory data and a basis for process optimization.

In an increasingly competitive market, reducing costs and increasing efficiency are no longer optional; they're imperatives. A small ESD Box/ESD Bins may hold the key to improving logistics efficiency and reducing operating costs for your business.

For details, please contact:

E-mail: [email protected]

Website: www.leenolesd.com