Electrostatic Discharge (ESD) poses an essential risk in manufacturing and assembling operations because industrial workplaces handle electronics. The fast static charge discharges can detrimentally affect lightweight electronic components therefore endangering both product quality and operation cost effectiveness and human security conditions. Organizations need to establish full-scale ESD protection methods because these strategies work to reduce potential risks. The following article explains essential approaches toward creating ESD protection programs while describing employee training and system maintenance methodology along with appropriate equipment selection for ESD applications and various grounding solutions and personal protective equipment requirements.

Establishing an ESD Protection Program

Any successful ESD protection initiative depends upon an organized ESD protection program as its fundamental basis. The development of a structured approach for identifying and minimizing ESD risks parameters in the workspace forms the core of the ESD protection program.

Training Employees on ESD Protocols

The success of an ESD protection program depends completely on the staff members performing the implementation tasks. Creating effective ESD protection systems depends on training all workers about ESD protocols. Educational training about ESD origins and the necessity of ESD control and preventive measures against ESD events must be performed to all employees on a scheduled basis.

Educational training systems combined with practical workshops along with operator demonstrations serve as effective tools to teach challenging concepts. Employees require instruction relative to correct ESD control tool methods including how to properly use antistatic mats along with wrist straps and ESD-safe clothing. Experienced employees achieve better knowledge retention by taking periodic assessments together with additional training which both renew their understanding of ESD procedures.

Routine Maintenance and Checks

Regular inspections of ESD protection measures stand as essential components in the ESD protection program because equipment performance degrades with time. Professional personnel should systematically inspect ESD control tools to verify their operational proper function.

The testing of ESD workstations as well as wrist straps and grounding points and other instruments must be performed regularly by using approved evaluation tools. Identified ESD faults along with performance inefficiencies must be handled quickly to stop possible damage from ESD sources. A well-kept inspection and maintenance log system allows for tracking fundamental performance metrics and provides data that supports future development initiatives.

Selecting Appropriate ESD Equipment

The selection of suitable ESD equipment stands essential for developing a protective static-free environment. The implementation of equipment selection must honor the precise requirements and workplace conditions present.

Workstations and Grounding Solutions

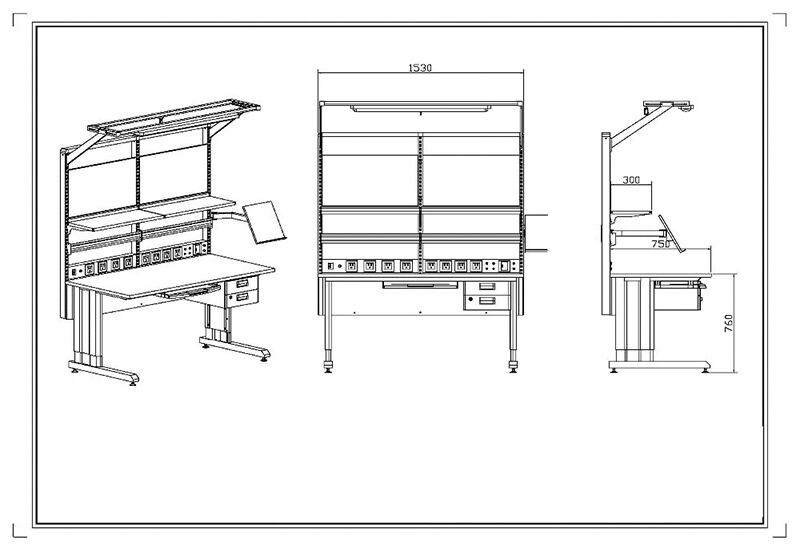

ESD-safe workstations function as a core element which prevents both static build-up and discharge occurrences. Workstations need to utilize conductive or dissipative components which will direct static electricity safely to the ground. ESD control becomes more effective through the implementation of grounded workbenches together with antistatic mats and appropriate flooring in the working environment.

Grounding solutions serve as fundamental equipment in ESD protection. Every workstation used for ESD protection needs an operational grounding system. Employee static charge accumulation prevention can be strengthened through the combined use of grounding wrist straps along with heel grounders and ESD footwear.

Personal Protective Equipment (PPE)

ESD control requires Part and Individual Protective Equipment (PPE) as a fundamental protective measure besides the implementation of workstations and grounding solutions. Workers must wear ESD-safe apparel such as lab coats together with gloves and proper footwear which suppresses static build-up during work actions.

Workers need to use ESD-safe gloves together with finger cots to prevent the transmission of static electricity during the handling of sensitive components. The proper grounding of workers while they move around the workplace becomes possible through the usage of ESD-safe footwear coupled with heel straps.

Conclusion

A successful integration of ESD protection within industrial environments demands multiple steps starting from creating ESD protection programs to providing employee training programs as well as maintaining equipment properly and selecting suitable ESD tools. By following these best practices, the industrial environment can reduce the risks associated with ESD, protect sensitive electronics, ensure the product integrity, and maintain a safe working environment.

In addition, continuous improvement and vigilance are important for success. Updating regular training programs, suiting new ESD technologies, and conducting regular check-ups will ensure that ESD protection measures remain effective and combine with the developed needs of the industrial work. Investment in ESD protection is not only about compliance, but also about the protection of overall productivity and long -term operating success.