The manufacturing industry makes continuous efforts to boost productivity together with diminishing their environmental consequences. ESD workbenches receive enhanced scrutiny because they represent an important element in safety procedures. Manufacturers inspect electrostatic discharge protection workstations designed to guard electronic components against disturbing discharges through multiple environmental sustainability assessments. This paper evaluates sustainability advancements in modern ESD workbenches through reusable resources combined with energy-efficient designs and environmentally approved standards while demonstrating their effectiveness in solar panel production sites.

Recyclable Materials and Energy Efficiency

The selection of materials during ESD workbench production directly affects ecological damage to the environment. These workbenches traditionally relied on different plastic and metal materials but most of those materials could not be reprocessed. The current trend in modern industry involves selecting eco-friendly materials for production. High-tech manufacturers have transitioned to producing workstations with recycled aluminum and steel besides using post-consumer plastics and sustainable forest products. The use of these materials serves two-fold purpose by reducing natural resource depletion while minimizing carbon emissions from workbench manufacturing and disposal phases.

Designers incorporate energy efficiency as an essential factor when working on ESD workbenches and their utilization. Modern manufacturing uses low-temperature curing together with energy-efficient machining processing techniques during the development of these workstations. New workbenches feature built-in energy-saving components as part of their design by modern companies. ESD-safe LED lighting gives electronic workers enough illumination through energy-efficient lighting methods that prevent traditional bulbs from being used.

Green Certifications

Little assessments show that manufacturers are environmentally conscious and customers can verify sustainable performance by certifying sustainable production claims. Manufacturers who seek certifications must meet specific environmental requirements which leads them to promote higher standards of sustainability. ESD workbenches require the LEED (Leadership in Energy and Environmental Design) certification as well as the ISO 14001 (Environmental Management Systems) certification for enhancing their environmental sustainability.

The approach targets major sustainability performance indicators that involve saving energy together with improving water efficiency and reducing CO2 emissions and creating better indoor environmental quality. Achieving LEED requirements forces producers to connect with materials that emit minimal pollutants while implementing renewable power generation systems together with organized waste disposal protocols.

ISO 14001 aids companies through its establishment of organized environmental duty management systems. A company becomes certified in ISO 14001 by establishing a permanent system which helps reduce environmental impact across production activities like material picking and waste order and resource management.

Case Study: Solar Panel Production

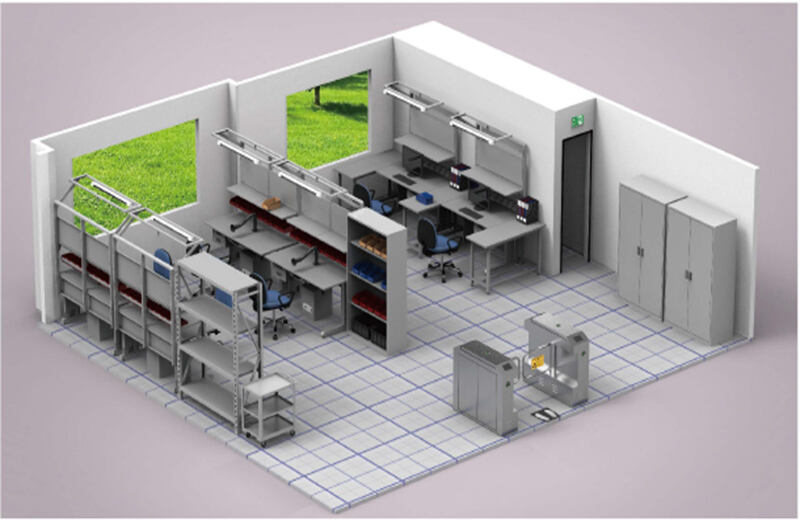

Companies operating in solar panel production and other relevant industries see significant environmental advantages from sustainable ESD workbenches because of their emphasis on green credentials. The production of solar panels establishes a fundamental link to environmental sustainability because it delivers more eco-friendly energy systems. The crucial performance of ESD workbenches guarantees the precise quality of electronic components which appear in solar panels.

The solar panel industry leader improved their production line with 85% recyclable material ESD workbenches. The companies selected workbenches that contained ESD-safe LED lighting systems for energy efficiency purposes. Their commitment to sustainability objectives achieves goals through these changes in energy management.

The organization continued to pursue LEED certification through widespread application of plant operational principles. Water conservation and energy reduction programs adopted within their operations included solar energy implementation which resulted in a considerable decrease of their environmental impact. An ISO 14001 environmental management system gave the company continuous abilities to inspect and enhance their green initiatives through systematic evaluation and monitoring procedures.

These steps demonstrate environmental advantages to manufacturers as well as positively impact their industry reputation. A brand with premium products combined with sustainable practices achieves distinction in markets focused on sustainability among customers and professional buyer-seller relations.

Conclusion

The move towards permanent manufacturing practices in the production and use of ESD workbench reflects a positive tendency in the industry. By preferring recycled materials, energy efficiency and green certificates, manufacturers can significantly reduce their environmental impact. Not only these practices ensure compliance with rapidly rigorous rules, but they also established a benchmark for industry standards to encourage the permanent initiative to be widely adopted. Case studies, such as people in the solar panel production sector, provide evidence of the real world of benefits and viability of such practices. Hugging these trends not only preserves our environment, but also promotes innovation and development within the manufacturing sector.