The performance of pick-and-place machines or reflow ovens is not the only factor that determines the reliability and performance of your SMT line in modern electronics manufacturing. The way printed circuit boards (PCBs) are handled and stored is one of the factors that should not be neglected. Selecting the right ESD-safe PCB magazine rack plays a critical role in ensuring smooth production, minimizing defects, and protecting sensitive components from electrostatic discharge.

Why ESD-Safe PCB Magazine Racks Matter

Electrostatic discharge is a major risk in electronic assembly. Even a small static shock can damage sensitive ICs or reduce their long-term reliability. PCB magazine racks designed to be ESD safe utilize safe conductive or dissipative materials that are engineered to direct, rather than conduct, static electricity away PCBs. In high-volume SMT lines, ordinary storage racks may be used, but this may introduce invisible damage that causes expensive field failures.

In addition, these SMT PCB Magazine racks mechanical protection as well and boards are firmly packed at racks in a storage, transfer, and automated process. To manufacturers interested in increasing throughput and reducing scrap rates, PCB storage options are directly correlated with productivity.

Key Considerations When Choosing an ESD Magazine Rack

1. Compatibility with SMT Line Equipment

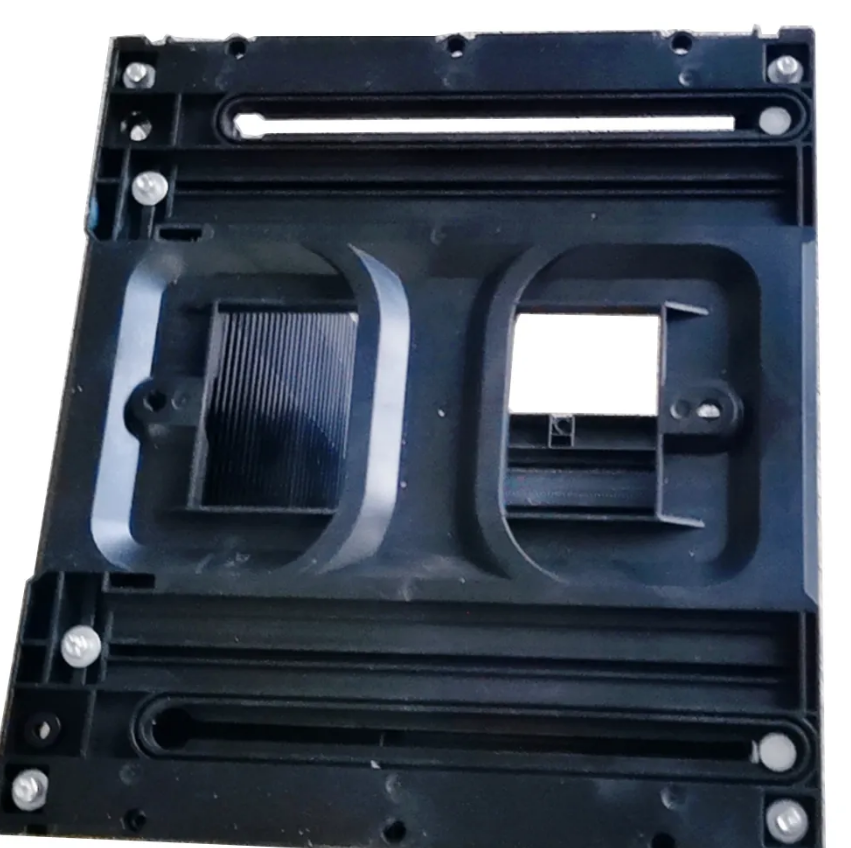

Not every magazine rack is designed for every loader, unloader, or conveyor system. Upon buying, make sure that the ESD magazine rack is compatible with your SMT automation equipment. This is rack width, height and indexing system. Choosing the wrong size can cause bottlenecks or require unnecessary adjustments to machinery.

2. Adjustable Capacity and Flexibility

Many SMT lines produce multiple board sizes. An efficient PCB magazine rack must be able to have dividers or side panels that can be changed to suit various PCB sizes. Flexibility reduces the need for multiple rack types, helping you optimize storage space and lower costs.

3. ESD Material Performance

The core function of an ESD-safe PCB magazine rack is protection against static discharge. Find SMT Magazine Racks consisting of high-grade conductive polypropylene, or metal reinforced materials that have demonstrated proven ESD properties. Verify that resistance values fall within industry standards (10⁴–10⁹ Ω), ensuring consistent protection across your entire production line.

4. Durability for Repeated Use

There is a periodical movement, stacking, and loading of racks onto conveyors by fast-moving SMT. It is imperative that it is lightweight and strong. Strengthened corners, durable surfaces, and heat resistance make the racks resistant to reflow, and long life without distortion or fracture.

5. Stackability and Ergonomics

For manufacturers dealing with large-scale PCB production, stackable PCB magazine racks help maximize floor space and streamline logistics. Ergonomic features, such as easy-grip handles and smooth edges, also improve operator safety and efficiency during handling.

6. Cost vs. Lifecycle Value

It can be easy to choose the lowest cost, but the B2B customers must examine the overall cost of ownership. A durable ESD magazine rack that lasts thousands of cycles often delivers higher ROI than lower-priced alternatives that need frequent replacement.

Benefits of Choosing the Right Rack

- Reduced PCB damage: Prevents costly failures caused by electrostatic discharge or mechanical stress.

- Improved production efficiency: Ensures smooth compatibility with loaders and conveyors.

- Lower operating costs: Extends the usable life of storage racks and reduces downtime.

- Scalable logistics: Supports lean manufacturing practices with efficient stacking and transport.

Conclusion

For electronics manufacturers, the correct EDS-safe PCB magazine rack is not only an accessory of storage, but it is an important element of the SMT process. Considering compatibility, adjustability, materials performance and durability B2B buyers are able to make sound decisions that improve quality production and protect fragile parts.

When selecting PCB storage products, make sure to consider racks that fit your needs in SMT line and provide reliable ESD protection. The correct decision will protect your products, optimise processes, and help to achieve success in the long-term manufacturing.